|

AC DETECTOR SENSORS

|

|

Sensor

Sensor

AC Sensor

|

I have made up many of these AC sensors.

They detect the failure of AC power. They detect low voltage and brownouts. They do not detect

phase reversal, but they do detect missing legs.

Optocouplers isolate high voltage from the system. The optoisolated sensors are necessarily part of a community and

part of a system.

Caution:

One must use high voltage leads with good insulation - no holes or cracks.

At 480 volts, a flashover may not extinguish itself untill major damage is done.

Or at least - a large fuse blows.

Use good insulating epoxy or silicone over the resistors to keep out moisture.

I have never had a flash over, and that is with many sensors, and over many years.

But one must be aware of the danger.

Use longer, or multiple, resistors in series.

Multiple resistors give a greater physical breakdown distance.

I have installed these sensors all over the place at several sites.

These sensors are cheap, and easily adjusted. Therefore for critical applications I have several

sensors looking at the same thing. I don't recall ever having an AC sensor fail. But redundancy can detect a sensor

failure, if such a failure should occur.

SITE AC

|

Setting up an ac sensor...

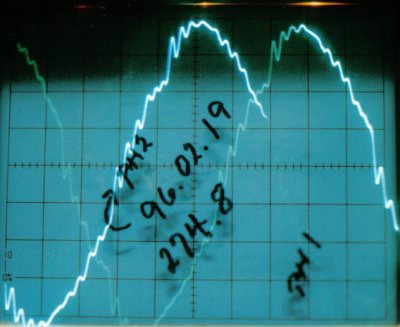

Phase one and phase two are shown.

One should know the normal imperfections in the wave form.

Broadcast sites are notorious for unusual waveforms.

This knowledge is important when making adjustments.

For example, if the pot adjustment is set too critical and the capacitor is too light, pulling the

trigger on a 200 watt

soldering gun can set off the sensor. So you must know what is likely to accur on the line(s).

Here is a picture:

In this example, much spiking is shown. The spiking is from high voltage rectifiers in a nearby HV power supply.

AC Sensor

(Non Latch)

|

Schematic

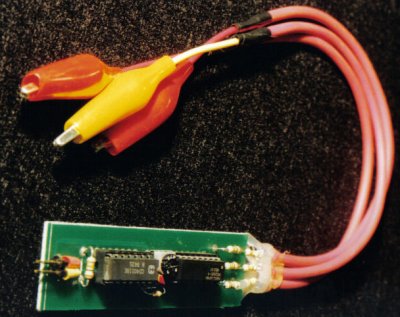

Years of experience have shown that alligator clips, holding on to AC Mains, work well.

They look temporary, but they work.

Yes, many sensors would look better if the leads were permanently under ties or rails.

But to place leads neatly under tie bolts and bars, one must remove all AC power. For over

14 years, operators have appreciated the clear results of these many sensors, despite the installation cosmetics.

Inexperienced

engineers - on the other hand - are a constant source of irritation.

I have built redundancy into my systems. But never the less, an alligator clip lead should never be casually lifted.

Generators will start in anticipation, and a transfer, although unlikely, may take place.

In any case, you will be talked to by overhead speakers. So do not do it unless you have told the system

in advance what you will be doing. The seriousness to the system should not be lightened by the fasteners.

AC SENSOR

(Latcher)

|

Another AC sensor was used in the early years from 1992 onward. The sensor is a latching AC sensor.

It was necessary with my old system. My old system could be too slow to catch fast events.

The heart of my old system was a computer. The computer handled everything, and as such could easily miss a

short event. Even if an event was not missed, the event could not be timestamped withen three or four seconds.

My old system

could not accurately place events in order of occurrence. My new system uses dedicated microprocessors at local levels

with timestamping withen about 10 milliseconds. Never the less, some of these AC sensors are still around.

A remote control pannel did not waist a control line for each sensor. Instead, one control line went to as many as 16 sensors.

All sensors were reset at the same time after the compter read a control pannel for all it's sensors.

The sensor is nothing to be proud of, as it was only a bandaid fix.

A comment is in order for the fast attack diode in between the opamps.

On my way to the site, the highway patrol had stopped traffic,

as one line was on the pavement.

By the look of many burn marks on the pavement, the line had been dancing and arcing.

A couple

of bushes were still smoking near the pavement edge.

The other two lines were still on the poles and were ok.

A failure condition of AC lines may be one of

one leg disconnected.

One condition is worse: one leg is intermittent. This condition places special demands on sensor abilities.

This two legged three-phase-system may give rise to fast cycling of good vs bad readings.

The first time this happened, many years ago, fanfold paper started reaming through the printer in master control.

Every second entry was this sensor indicating PGE bad, followed by PGE good. The printer was going crazy

and the speech module was saying PGE is good, then PGE is bad. It would not shut up. Total chaos!

On and on, the entries came, untill the

upper limit of entries per 10 minutes was reached. Printing was haulted with the last entry as "VERBOSE PRINTING HAULT".

The fast attack diode insures that the sensor goes down and stays down, in the AC BAD state, no matter what strange leg configurations.

Also, in those early years, redundancy was found and valued.

All my sensors were designed in the real world. In this world, others dread a failure; I welcome with open arms such a glorious event.

Sensor

Sensor