Second Solar DC to DC Controller

|

|

|

|

Solar Controlling and Charging

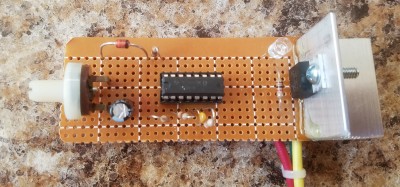

Here are my objectives with this charger. Before I begin, I will create a starting point. Here is my basic regulator before I begin developing...

Before I begin, I will create a starting point. Here is my basic regulator before I begin developing...

I am still using the same P-Channel MOSFET IRF4905.

I am still using the same P-Channel MOSFET IRF4905. In my first design using a PIC to control the MOSFET, I had no problems with regulation.

It was a variable frequency, and variable Pulse Width: It was what I call a simple Chaotic regulator, and it worked good.

Now I am using the TL594 PWM chip driving a power MOSFET IRF4905, actually four TL594s driving four IRF4905s

And before with the first design, a PIC performed the intrinsic manipulation of the MOSFET.

Now the PWM chip operates the MOSFET, and with such exclusive dedication, higher speeds are possible, as well as more smoother and consistent operation.

In my first design using a PIC to control the MOSFET, I had no problems with regulation.

It was a variable frequency, and variable Pulse Width: It was what I call a simple Chaotic regulator, and it worked good.

Now I am using the TL594 PWM chip driving a power MOSFET IRF4905, actually four TL594s driving four IRF4905s

And before with the first design, a PIC performed the intrinsic manipulation of the MOSFET.

Now the PWM chip operates the MOSFET, and with such exclusive dedication, higher speeds are possible, as well as more smoother and consistent operation.

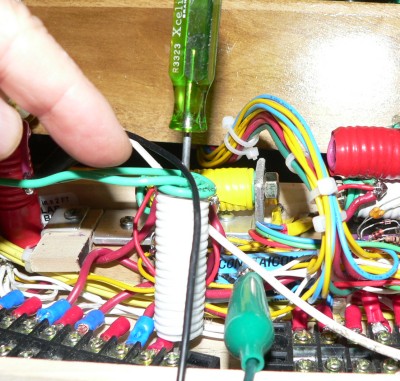

Fascinating to put a screwdriver into an open air inductor. The air inductor is cool to the touch without the iron inside.

However, if you put a screwdriver shaft inside the choke,

and leave it there for a half minute,

and then pull it out, then you will find the shaft too hot to safely touch.

Fascinating to put a screwdriver into an open air inductor. The air inductor is cool to the touch without the iron inside.

However, if you put a screwdriver shaft inside the choke,

and leave it there for a half minute,

and then pull it out, then you will find the shaft too hot to safely touch.

This is with the screwdriver inserted inside the coil.

Inductance increases dramatically.

Reactive component increases, but the resistive component dominates by killing changes by turning them into heat.

Changes do not linger.

Don't touch the blade of the screwdriver when you pull it out!

This is with the screwdriver inserted inside the coil.

Inductance increases dramatically.

Reactive component increases, but the resistive component dominates by killing changes by turning them into heat.

Changes do not linger.

Don't touch the blade of the screwdriver when you pull it out!

|

|

|

Here is heavier current.

Here is heavier current.  I built the inclosure prematurely. The box is too small. Nothing fits.

I am using an old fashioned analog amp meter. It shows 2.7 amps. The one amp meter shows the total current to all four loads.

The loads are two battery banks, one utilities, and one reject load. Three dedicated meters are shown in blue; They two battery banks and one remote Utilities.

I built the inclosure prematurely. The box is too small. Nothing fits.

I am using an old fashioned analog amp meter. It shows 2.7 amps. The one amp meter shows the total current to all four loads.

The loads are two battery banks, one utilities, and one reject load. Three dedicated meters are shown in blue; They two battery banks and one remote Utilities.

Removed the third coil on input. There are now only two Chokes of #12 wire air coils of 3.52uH, 3.79uH.

Removed the third coil on input. There are now only two Chokes of #12 wire air coils of 3.52uH, 3.79uH.  Input Electrolytic gets warmer without that coil. But I am going to leave it out. Input regulation is not that important.

Just so the PIC can get an accurate measure of the input voltage from the solar panels under load. And it is solid.

However, the electrolytic will not last very long at 102F degrees, but I will worry about it later.

Building this thing may take awhile; I make a gain in one place and loose in another.

Input Electrolytic gets warmer without that coil. But I am going to leave it out. Input regulation is not that important.

Just so the PIC can get an accurate measure of the input voltage from the solar panels under load. And it is solid.

However, the electrolytic will not last very long at 102F degrees, but I will worry about it later.

Building this thing may take awhile; I make a gain in one place and loose in another.

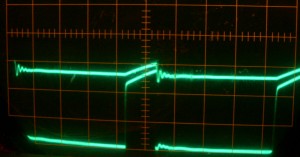

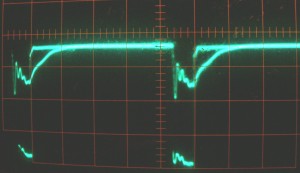

Output Regulation is OK from a no load of 13.00volts, to a 2.6A load of 12.99volts. Difference 0.01v at 2.6A

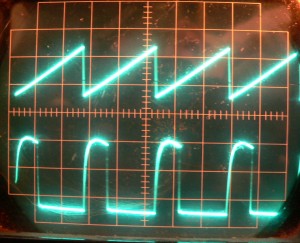

Output Regulation is OK from a no load of 13.00volts, to a 2.6A load of 12.99volts. Difference 0.01v at 2.6A PWM starts at the upper part of the slope, and deepens with more demand to the left.

Actually, a more logical way to look at it is that the slope begins at the bottom, rises (tests the water) until the output matches slope voltage.

The conduction period is triggered. The earlier the trigger, the lower was the output voltage.

PWM starts at the upper part of the slope, and deepens with more demand to the left.

Actually, a more logical way to look at it is that the slope begins at the bottom, rises (tests the water) until the output matches slope voltage.

The conduction period is triggered. The earlier the trigger, the lower was the output voltage.

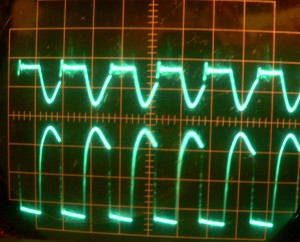

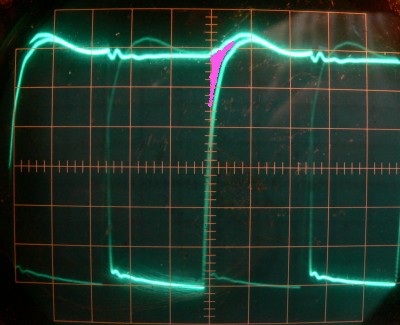

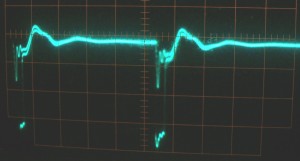

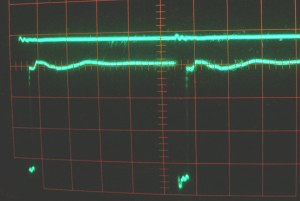

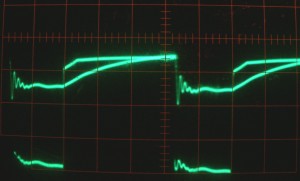

Here is a huge load and a huge amount of current to maintain the same voltage.

On the scope you can see the source voltage drops, less ripple in the input, and the conduction time increases.

The PWM timing remains the same. (I had my fingers on the scopes sweep speed.)

Here is a huge load and a huge amount of current to maintain the same voltage.

On the scope you can see the source voltage drops, less ripple in the input, and the conduction time increases.

The PWM timing remains the same. (I had my fingers on the scopes sweep speed.)

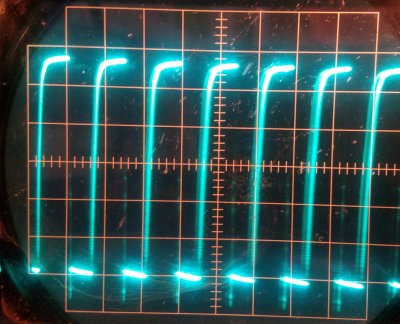

Top trace is the MOSFET Source voltage. Bottom trace is the MOSFET Gate voltage. They kinda merge together at the top. |

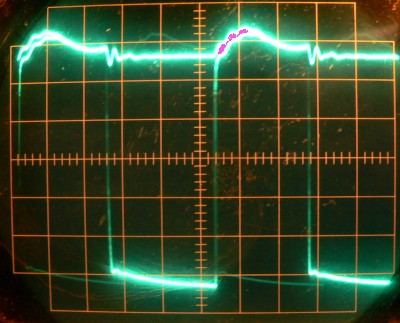

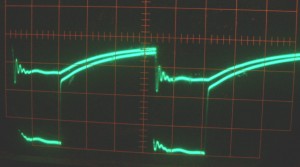

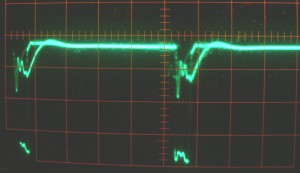

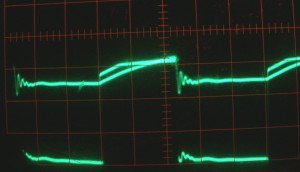

Wow! that really improved the up stroke. Sides are straight.

Wow! that really improved the up stroke. Sides are straight.  Input: 14.76v, 2.71A, 40w

Input: 14.76v, 2.71A, 40w Here is the box, split into two: a top and a bottom.

Here is the box, split into two: a top and a bottom. I can use these speaker rheostats to soften the input.

I am using the automotive bulbs for loads.

Each bulb can use about 3 amps using both filaments.

This test setup is essential.

I can use these speaker rheostats to soften the input.

I am using the automotive bulbs for loads.

Each bulb can use about 3 amps using both filaments.

This test setup is essential.

OK, I think I have got it. I built this Gate Driver. It is a Peak-Hold.

I could have used a germanium .3v diode but a silicon 0.6v does the job great.

OK, I think I have got it. I built this Gate Driver. It is a Peak-Hold.

I could have used a germanium .3v diode but a silicon 0.6v does the job great.

I might leave the mechanical switcher hanging on the wall. It can withstand an EMP attack.

One the other hand, it is a relick that my wife may bump her head on, and then we have real problems.

I might leave the mechanical switcher hanging on the wall. It can withstand an EMP attack.

One the other hand, it is a relick that my wife may bump her head on, and then we have real problems.

Works in the RV at high currents too. I am using 12 amps for my soldering gun all the time.

And my drill pulls about 15 amps. Both of these come from the 120 volt inverter.

I am fascinated how one FET in this tiny regulator does not get warm.

I hammered it with 12 amps from my soldering gun for 30 secs, and there was no detectable warmth.

But the day will come when I will need more current,

and for perhaps no more of a reason than esthetics, will have to make it at least look larger.

I need not worry about heat in this small board as it only drops about 3 volts; no special drive or coils.

Works in the RV at high currents too. I am using 12 amps for my soldering gun all the time.

And my drill pulls about 15 amps. Both of these come from the 120 volt inverter.

I am fascinated how one FET in this tiny regulator does not get warm.

I hammered it with 12 amps from my soldering gun for 30 secs, and there was no detectable warmth.

But the day will come when I will need more current,

and for perhaps no more of a reason than esthetics, will have to make it at least look larger.

I need not worry about heat in this small board as it only drops about 3 volts; no special drive or coils.

Here is the PostReg inside the Fuse Box. The red light is coming from the LED that drives the gate.

It flickers, changing intensity according to the load. I like to be able to "see" the regulation.

And to see it, I do not mind cutting out a couple of vents.

Here is the PostReg inside the Fuse Box. The red light is coming from the LED that drives the gate.

It flickers, changing intensity according to the load. I like to be able to "see" the regulation.

And to see it, I do not mind cutting out a couple of vents.

Here is the Solar Collection Panel...

Here is the Solar Collection Panel... Here Battery-one is in equalize mode and is pulling almost 9 amps. There are two solar flux sensors.

Both are mounted on the Air Conditioner. The Controller has its own dedicated sensor and it reads 42%.

Characteristically for this location at Black Butte, with some oak limbs overhead, you can devide the solar input percent by, an arbitrarily and roughly, "three" to get the max amps.

In this case 42/3=14 amps max possible.

Early this morning with pure sky light and little shadings, 1.0% solar input, which is where things begin to work, was producing roughly 300mA.

Of course, if I wanted it more exact, I could look at, and test, each panel individually exactly with the switches at the Collection Panel.

A general collection from the intire roof is more convenient, because no dought some panels may be shaded.

The RV can be in full sun, and yet a pedicular panel can be shaded by a leaf, or shaded by the Air Conditioner, or the antenna if it is up.

And inherent shading from objects on the roof is worse at low sun angles of the morning and evening.

Here Battery-one is in equalize mode and is pulling almost 9 amps. There are two solar flux sensors.

Both are mounted on the Air Conditioner. The Controller has its own dedicated sensor and it reads 42%.

Characteristically for this location at Black Butte, with some oak limbs overhead, you can devide the solar input percent by, an arbitrarily and roughly, "three" to get the max amps.

In this case 42/3=14 amps max possible.

Early this morning with pure sky light and little shadings, 1.0% solar input, which is where things begin to work, was producing roughly 300mA.

Of course, if I wanted it more exact, I could look at, and test, each panel individually exactly with the switches at the Collection Panel.

A general collection from the intire roof is more convenient, because no dought some panels may be shaded.

The RV can be in full sun, and yet a pedicular panel can be shaded by a leaf, or shaded by the Air Conditioner, or the antenna if it is up.

And inherent shading from objects on the roof is worse at low sun angles of the morning and evening.

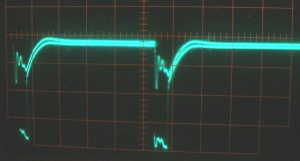

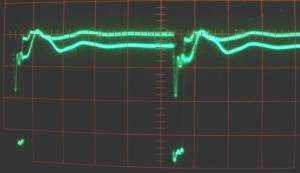

Here I am using the "LED Drive" and not the Totem Pole, but the point is that I have adjusted the duty cycle to about 50% to achieve maximum heating of the FET capacitor,

and maximum switching losses in the FET. The sides are straight enough on the down stroke, but not on the return up to nonconduction.

Here I am using the "LED Drive" and not the Totem Pole, but the point is that I have adjusted the duty cycle to about 50% to achieve maximum heating of the FET capacitor,

and maximum switching losses in the FET. The sides are straight enough on the down stroke, but not on the return up to nonconduction.

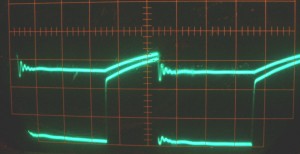

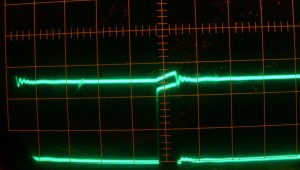

Here I have increased the input cap size to 0.47uF. Also, I have moved it to capture better CMR with the negative input.

Here, with low loading, there are Skipped Cycles, but no hash.

Here I have increased the input cap size to 0.47uF. Also, I have moved it to capture better CMR with the negative input.

Here, with low loading, there are Skipped Cycles, but no hash.

The panels are capable of over 40 amps. So you may wonder why fuses of only 15 amps.

The reason is that the RV is designed for the fog and rain.

At present, I am only concerned charging current per battery.

This is a replenishment current, not the maximum current from the batteries that can be used.

A 20 amp inrush current to recharge a dead battery is possible.

But fortunately the sun comes up slowly, and a lot of pre charging takes place before any sudden hits can be delivered.

Actually, the first time these fuses go, I will replace them with 25 amps. Why am I trying to rationalise a stupid thing?

The panels are capable of over 40 amps. So you may wonder why fuses of only 15 amps.

The reason is that the RV is designed for the fog and rain.

At present, I am only concerned charging current per battery.

This is a replenishment current, not the maximum current from the batteries that can be used.

A 20 amp inrush current to recharge a dead battery is possible.

But fortunately the sun comes up slowly, and a lot of pre charging takes place before any sudden hits can be delivered.

Actually, the first time these fuses go, I will replace them with 25 amps. Why am I trying to rationalise a stupid thing?

Now, maybe, that will be the last problem, and I can get back to having fun at Black Butte.

Now, maybe, that will be the last problem, and I can get back to having fun at Black Butte.