2 Samuel 22:29

|

RV Maintenance My Stove as an RV Heater |

THE NEED FOR AN ALTERNATE HEATING SOURCE

There had been little sun for days, just fog and rain. On the second night of near freezing temperatures, I could see we had a problem. I only have one battery, and it had never been adequately recharged with no direct sun. In the dismail rain, ambient light could only muster a little over one amp: that equates to only about 10 amp-hours a day. That furnace of mine is eating up 30 amp-hours a day! It does not take a rocket scientist to predict a fast approaching cold future. My one battery is an old 100 amphour battery that is almost depleted of all reserves.|

2 Samuel 22:29 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Apply grease

Apply grease

|

Inclosed and sealed.

Inclosed and sealed.

|

Pretty nob

Pretty nob

|

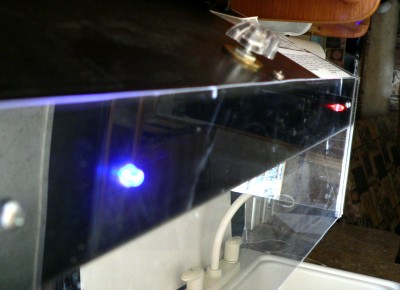

Hood indicators

RGB: 5,000mcd, 5v, 0.2w, 30deg

Blinking Red: 0.2 Lumen, 2000mcd, 0.175 Watts, 10v

Hood indicators

RGB: 5,000mcd, 5v, 0.2w, 30deg

Blinking Red: 0.2 Lumen, 2000mcd, 0.175 Watts, 10v

|

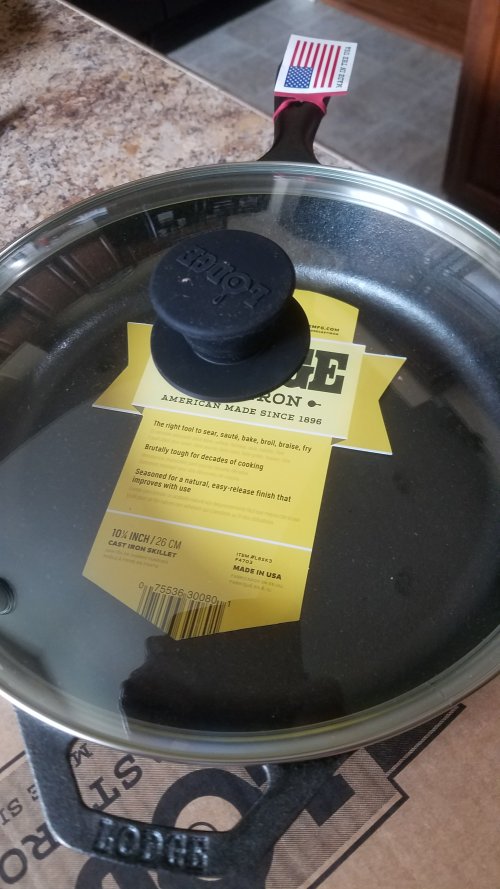

Originally, before I rediscovered Cast Iron, I had tried modern pots, like Ceramic.

But discovered that they leach Aluminum from their rims. Seems to be a problem and health concern of all Ceramic pots and pans.

So, I switched back to Cast Iron like my Mom used. No food has ever tasted better than what was cooked in my Mom's Cast Iron.

I did not intend to buy Lodge, but I made the mistake of only looking on Amazon.

Amazon does not cover better brands such as Field, and StarGazer.

Lodge is too heavy for an RV, about 8 pounds including a lid. Modern skillets are only a couple of pounds.

The weight part is great, but modern skillets can not be used due to health concerns.

Originally, before I rediscovered Cast Iron, I had tried modern pots, like Ceramic.

But discovered that they leach Aluminum from their rims. Seems to be a problem and health concern of all Ceramic pots and pans.

So, I switched back to Cast Iron like my Mom used. No food has ever tasted better than what was cooked in my Mom's Cast Iron.

I did not intend to buy Lodge, but I made the mistake of only looking on Amazon.

Amazon does not cover better brands such as Field, and StarGazer.

Lodge is too heavy for an RV, about 8 pounds including a lid. Modern skillets are only a couple of pounds.

The weight part is great, but modern skillets can not be used due to health concerns.

I was worried that it would not fit. It has to fit in the oven for storage. In an RV, SPACE is sacred. Every inch.

The oven is 15.5 inches by 15.5 inches: it fits OK. The old pan is not a skillet. I think it is classified as a "pan". Although, I cook eggs and potatoes in it as if it were a skillet. Everything goes back to what an RV is: Every thing has a space, and everything has AT LEAST ONE usage, preferable more. In this case, I can also make stir-fry.

But there are problems:

I was worried that it would not fit. It has to fit in the oven for storage. In an RV, SPACE is sacred. Every inch.

The oven is 15.5 inches by 15.5 inches: it fits OK. The old pan is not a skillet. I think it is classified as a "pan". Although, I cook eggs and potatoes in it as if it were a skillet. Everything goes back to what an RV is: Every thing has a space, and everything has AT LEAST ONE usage, preferable more. In this case, I can also make stir-fry.

But there are problems:

The CENTER of a ten inch skillet must fit directly over a burner. It does; just barely.

But I still feel, without knowing, that a ten inch is too big for this small stove.

But, if I am really hungry, more hungry than 10 inches, I can live with it.

The other problem is that cast holds a lot of heat, and that sink that you see there, is PLASTIC.

If I have any brains, I will not be just throwing that kind of a hot skillet into the sink.

If I forget, the sink may no longer hold water.

One solution, it would cost more money, but I could replace the sink with stainless.

That brings me to another problem: weight.

A stainless sink will weigh more than this plastic one.

Remember, this is an RV. And... Did I mention the skillet weighs a ton, with lid, about 8 pounds?

The CENTER of a ten inch skillet must fit directly over a burner. It does; just barely.

But I still feel, without knowing, that a ten inch is too big for this small stove.

But, if I am really hungry, more hungry than 10 inches, I can live with it.

The other problem is that cast holds a lot of heat, and that sink that you see there, is PLASTIC.

If I have any brains, I will not be just throwing that kind of a hot skillet into the sink.

If I forget, the sink may no longer hold water.

One solution, it would cost more money, but I could replace the sink with stainless.

That brings me to another problem: weight.

A stainless sink will weigh more than this plastic one.

Remember, this is an RV. And... Did I mention the skillet weighs a ton, with lid, about 8 pounds?

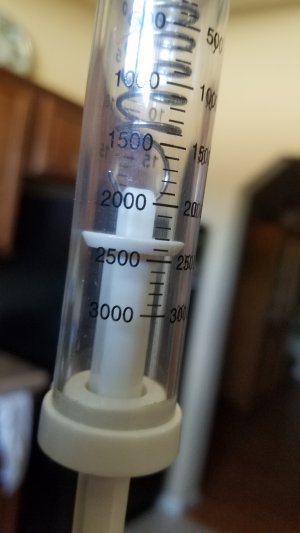

Here is the weight of the Lodge on a Suspension scale.

2320 grams is 5.114 lbs for the Lodge. Yes, that is heavy! I do not really want to use it in an RV.

Here is the weight of the Lodge on a Suspension scale.

2320 grams is 5.114 lbs for the Lodge. Yes, that is heavy! I do not really want to use it in an RV.

The StarGazer measures the same: 5.1 lbs.

The StarGazer measures the same: 5.1 lbs. There are actions of others that go beyond misleading - They can hurt you!

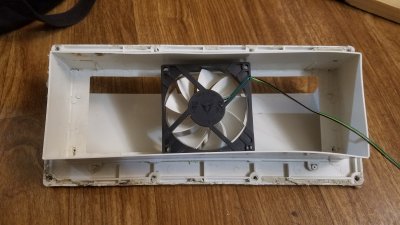

There are actions of others that go beyond misleading - They can hurt you! I bought a fan...

I bought a fan... My helper Callie...

My helper Callie...  This is how a single fan will be placed...

This is how a single fan will be placed...

Here the vent assembly is hanging on the outside of the trailer by gorilla tape while I get the wires soldered and secured.

Here the vent assembly is hanging on the outside of the trailer by gorilla tape while I get the wires soldered and secured.

A look inside the vent opening. You can see the big stove top vent fan. You can see two of the copper tubes on the right.

Nothing is cleaned yet.

A look inside the vent opening. You can see the big stove top vent fan. You can see two of the copper tubes on the right.

Nothing is cleaned yet.

Here is the outside vent cover just held in place to test everything.

The flapper door does not close totally shut. It hangs with a small gap. I do not think it is a problem.

Here is the outside vent cover just held in place to test everything.

The flapper door does not close totally shut. It hangs with a small gap. I do not think it is a problem.

This view is from the top of the stove looking up through the vent hood. There is no filter, so you can see the big stove top fan.

In addition, looking past the blades, you can see the newly installed small fan that will function for the oven, and also the Oven-Heater.

This view is from the top of the stove looking up through the vent hood. There is no filter, so you can see the big stove top fan.

In addition, looking past the blades, you can see the newly installed small fan that will function for the oven, and also the Oven-Heater.

With the big fan turned onn, and the speed adjusted to maximum, you have a better view of the small fan.

The flapper still opens almost all the way, even with a hole cut in the middle for the small fan.

With the big fan turned onn, and the speed adjusted to maximum, you have a better view of the small fan.

The flapper still opens almost all the way, even with a hole cut in the middle for the small fan.

Here is with the screen installed and the Stove Top Blocker. Magnets hold the Blocker shut. Now oven gasses are power vented to the outside.

Now I need to see if Callie is ready to go test it at that same lake. I believe she is ready to go and all packed.

Here is with the screen installed and the Stove Top Blocker. Magnets hold the Blocker shut. Now oven gasses are power vented to the outside.

Now I need to see if Callie is ready to go test it at that same lake. I believe she is ready to go and all packed.

Here is the fan:

Here is the fan: In the equation for the combustion of Propane, I need all reactants to be gasses.

In the equation for the combustion of Propane, I need all reactants to be gasses.