|

RV Maintenance Hot Water in the shower |

|

Water Diagram of RV

|

|

|

|

|

|

|

|

|

|

|

|

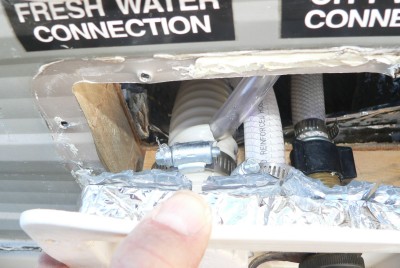

While the trailer had been sitting idle for a couple of weeks, one of the pex hoses pulled out.

Water went everywhere. The pex had pulled totally out during the cool night.

I got to the problem withen a few hours.

By the time that I had arrived, most of the water had exited the floor area by going down

the floor hole that the pex lines had come up through.

The water then went through the fiberglass insulation below the floor.

Under the trailer, I lay on my back looking for the missing water.

The water was pooled in the belly fabric, in an area between it's supports.

The belly fabric was seriously bowed down from the water weight.

And I could push the bulge

back up, and tell it was full of water. The bulge was heavy like water, and would migrate

around like water. There it was. I took a knife and lacerated the bulge in the center.

Water came pouring out, and gushed all over the ground. My arm was totally soaked,

and the water just barely missed my head.

After a couple of minutes, the water continued to drip as I widened the cut to view

the damage. Above the wet insulation all wood was dry. What a relief! I widened the cuts to allow

air to dry out the under area.

While the trailer had been sitting idle for a couple of weeks, one of the pex hoses pulled out.

Water went everywhere. The pex had pulled totally out during the cool night.

I got to the problem withen a few hours.

By the time that I had arrived, most of the water had exited the floor area by going down

the floor hole that the pex lines had come up through.

The water then went through the fiberglass insulation below the floor.

Under the trailer, I lay on my back looking for the missing water.

The water was pooled in the belly fabric, in an area between it's supports.

The belly fabric was seriously bowed down from the water weight.

And I could push the bulge

back up, and tell it was full of water. The bulge was heavy like water, and would migrate

around like water. There it was. I took a knife and lacerated the bulge in the center.

Water came pouring out, and gushed all over the ground. My arm was totally soaked,

and the water just barely missed my head.

After a couple of minutes, the water continued to drip as I widened the cut to view

the damage. Above the wet insulation all wood was dry. What a relief! I widened the cuts to allow

air to dry out the under area.

|

|

After an hour on the road, the curtain will be unfurled. It never puts itself away.

No, it will do the opposite of what you want.

So, to fix the problem, install a curtain holder.

Being an engineer, I could have used a high tech magnetic holder.

But these take too much effort.

This, however is easy. Not too much more than just throwing the curtain open.

After a shower, something that you would do anyway.

And Linda says it looks better too.

The big glass door-nob-thing does not turn, and helps the slick curtain to slide in.

Linda says it is to look at.

After an hour on the road, the curtain will be unfurled. It never puts itself away.

No, it will do the opposite of what you want.

So, to fix the problem, install a curtain holder.

Being an engineer, I could have used a high tech magnetic holder.

But these take too much effort.

This, however is easy. Not too much more than just throwing the curtain open.

After a shower, something that you would do anyway.

And Linda says it looks better too.

The big glass door-nob-thing does not turn, and helps the slick curtain to slide in.

Linda says it is to look at.

You do not want to stay in Northern California very long: here the temperature is over 100 degrees.

I am getting the job completed just in time to get out of here.

You do not want to stay in Northern California very long: here the temperature is over 100 degrees.

I am getting the job completed just in time to get out of here.

I finally fixed another problem:

I finally fixed another problem: And then mounted these dispensers... And that solved that!

The one on the right is shampoo, and it is a mixture of a white antidrandruff shampoo and a Green Tea shampoo;

All swirled together without mixing very well. Kinda pretty.

You judge the amount of dispensed soap by the amount of pull distance.

A full pull is a lot of soap. For me, about a quarter pull is about right.

In an RV, you must keep soap a little on the meager side,

or else you will spend unnecessary time washing it out, and waisting water.

And no way around that one: You WILL use more water washing out soap!

And then mounted these dispensers... And that solved that!

The one on the right is shampoo, and it is a mixture of a white antidrandruff shampoo and a Green Tea shampoo;

All swirled together without mixing very well. Kinda pretty.

You judge the amount of dispensed soap by the amount of pull distance.

A full pull is a lot of soap. For me, about a quarter pull is about right.

In an RV, you must keep soap a little on the meager side,

or else you will spend unnecessary time washing it out, and waisting water.

And no way around that one: You WILL use more water washing out soap!

|

|

Luke 11:11 |

|

|

|

|

|

|

|

|

At BlackButte Lake to "test out the shower".

At BlackButte Lake to "test out the shower".

|

But this sink works great!

But this sink works great!

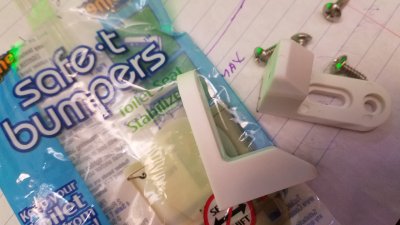

The original toilet seat of cheap plastic cracked around bolts. Finally the hinge totally broke off on the left side.

Now, the damn thing would slip and slide around - even on level ground. You got to hang on for dear life.

I repaired it with epoxy, to only have it brake again a week later.

Before the fatal final break, there were two additional fractures in the cheap plastic.

I could buy an exact replacement for under $10 bucks. But why?

This lid only lasted me about 8 years. The plastic degrades rapidly.

The original toilet seat of cheap plastic cracked around bolts. Finally the hinge totally broke off on the left side.

Now, the damn thing would slip and slide around - even on level ground. You got to hang on for dear life.

I repaired it with epoxy, to only have it brake again a week later.

Before the fatal final break, there were two additional fractures in the cheap plastic.

I could buy an exact replacement for under $10 bucks. But why?

This lid only lasted me about 8 years. The plastic degrades rapidly.

So, I purchased a "real" lid. This one is made of Oak with real brass hinges. Pretty too!

If you choose wood, you should revarnish it for good measure, otherwise moisture could penetrate wood sections or seams, and split the wood.

This is a major complaint of wood in a hot steamy enviroment.

So, I purchased a "real" lid. This one is made of Oak with real brass hinges. Pretty too!

If you choose wood, you should revarnish it for good measure, otherwise moisture could penetrate wood sections or seams, and split the wood.

This is a major complaint of wood in a hot steamy enviroment.

But even this real lid will not last without additional modifications.

The additional modifications are required for any lid, especially those in an RV. The problem arises with sideways force on the seat.

I am not particularly heavy, at 170 lbs. But in a closed space, like in an RV, you can not reposition your weight on the seat.

The hinges made of any material will not tolerate the side forces. Nylon bolts will not work; as they strip out, and also can never be kept tight.

Metal bolts force the fracture of the hinge itself, if not the ceramic. But there is a neat solution...

But even this real lid will not last without additional modifications.

The additional modifications are required for any lid, especially those in an RV. The problem arises with sideways force on the seat.

I am not particularly heavy, at 170 lbs. But in a closed space, like in an RV, you can not reposition your weight on the seat.

The hinges made of any material will not tolerate the side forces. Nylon bolts will not work; as they strip out, and also can never be kept tight.

Metal bolts force the fracture of the hinge itself, if not the ceramic. But there is a neat solution...

One side is sloped or beveled because with such close tolerances,

the toilet seat is given an opportunity to automatically seat itself before the seat is all the wall down. It is guided into place.

One side is sloped or beveled because with such close tolerances,

the toilet seat is given an opportunity to automatically seat itself before the seat is all the wall down. It is guided into place.

My wife likes the cover down. I do not know why. Actually, I do. Or at least a reason: the bottom drawer will not have room to open with the cover up.

Another stupid mistake from Keystone...

My wife likes the cover down. I do not know why. Actually, I do. Or at least a reason: the bottom drawer will not have room to open with the cover up.

Another stupid mistake from Keystone...