|

|

Magnets found around the house |

|

I am crazy about magnets.

Permanent magnets are used everywhere, and I love finding them.

You can learn so much from each magnet that you find about your house.

I have found measuring the intrinsic magnetic strength of all my magnets is easy and fun.

And the strength even corresponds to what my magnets are made of.

The following magnets that I have around the house use this equation...

The following magnets that I have around the house use this equation...

(I have derived this equation on other pages.)

Or, solving for Br...

Or, solving for Br...

The Br of all my magnets around the house:

z is the distance away from the magnet face.

z is the distance away from the magnet face.

L is the thickness.

L is the thickness.

R is the equivalent radius of the two frontal face dimensions.

R is the equivalent radius of the two frontal face dimensions.

Bz is the magnetic strength at the z distance.

I use the equivalent radius R.

Bz is the magnetic strength at the z distance.

I use the equivalent radius R.

AlNiCo Br Br Hc Hc Hneed Hneed BHmax BHmax -0.04 300 750

Alnico-2 Isotropic cast 7.5kG 750mT 45 kA/m 1490F

Alnico-2 Isotropic sint 7.1kG 710mT 44 kA/m

Alnico-5 Anisotropic cast 12,500G, 1250mT 640 Oe, 51 kA/m 3000 Oe, 240kA/m 5.50 MGOe, 43.8 kJ/m3 -0.02 540 860 975F

Alnico-5 Anisotropic sint 10,900G, 1090mT 620 Oe, 49 kA/m 1000F

Alnico-800 13,700G, 1370mT 740 Oe, 59 kA/m 3000 Oe, 240kA/m 8.10 MGOe, 64.5 KJ/m3

Alnico-8 Anisotropic cast 8.2 kG, 820mT

Alnico-8 Anisotropic Sint 7.4 kG, 740mT

Alnico is the only magnetic that can be operated and heated over 1000 degrees F

and still have useful magnetism.

(Currie point is 1,470 degF.)

Alnico is temperature stable.

Generally sintered Alnico is less dense than Cast: 7g/cm3 or less for sintered, and 7.3g/cm3 for cast.

Alnico is easily demagnetized. Therefor, you must keep the ratio of length to face as large as possible.

And usually requiring Alnico magnets to be "long" magnets.

I have had additional Alnico magnets from: a tracter engine's Magneto which are horseshoe shaped, from Microphones, Meters, and a Cow-Magnet.

Speaker magnet

|

Alnico Speaker magnet-#1

2.1cm diameter

1.6cm Length

R=1.0 cm

North 5.68mT at one radius, Br=50.2mT

South 6.16mT at one radius, Br=53.9mT

Very week magnet. Evidently demagnetized.

These next three are much better: twice as strong.

These next three are much better: twice as strong.

I believe these were dissasymbled out of speakers in the 1950s.

I personally probably played with these very same magnets as a child.

Alnico Speaker magnet-#2

2.3cm diameter

1.35cm Length

Br=99.3mT

Alnico Speaker magnet-#3

2.5cm diameter

1.6cm Length

Br=98.7mT

Alnico Speaker magnet-#4

2.85cm diameter

1.93cm Length

Br=103.1mT

Alnico Hard Drive magnet

|

Alnico Hard Drive

10.21cm internal length on z axis

10.20cm face width

3.05cm to 2.65cm face height

Br=140mT

(Sorry. This magnet is not found "around-the-house".)

Rare Earth Magnet: Compounds come from the rare earth or Lanthanide series of the periodic table.

Rare Earth Magnet: Compounds come from the rare earth or Lanthanide series of the periodic table.

Samarium-cobalt magnet

(SmCo5, Sm2Co17)

1970'S

fragile and flammable

Quiet (for pickups, not microphonic)

and temperature stable.

Rare Earth Magnet: Compounds come from the rare earth or Lanthanide series of the periodic table.

Rare Earth Magnet: Compounds come from the rare earth or Lanthanide series of the periodic table.

Powdered NdFeB material is packed in molds, then sintered.

If a glue is also used, it is a sintered and bonded magnet.

Material Nd2Fe14B

Neodymium Iron Boron, NdFeB

"NIB", "Neo" magnet

Br Br Hci BHmax

Sintered Br=1200mt Hci=1000kA/m BHmax=300kJ/m3

bonded Br= 700mT Hci= 700KA/m BHmax= 75kJ/m3

BN-8 6,500G 650mT

BN-10 7,000G 700mT 220F

BN-12 7,600G 260F

from PC Hard Drive

|

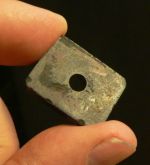

A Neodymium magnet

Chrome or nickel plated. In this example, plating is flaking off...

Under the plating, you can see that neodymium looks similar to a ferrite.

1.7cm 1.6cm 2mm

R=0.93cm radius equivalent

B=29.76 mT at one radius,

Br=916mT

(agrees well)

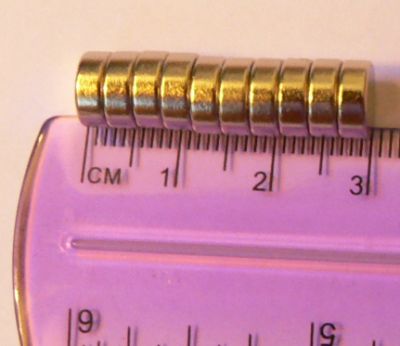

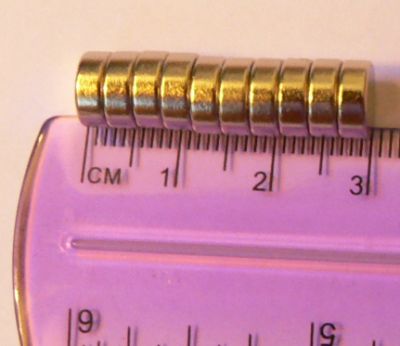

Hard Drives Neos

|

Once you know where to find these things, you can have gobs...

All these magnets were "duals".

On some brands of disk drives the individual magnets are glued unto the keeper.

They are two seperate magnets on a single keeper. On the other type, both magnets are

manufactured as one piece.

In ether case, the configuration is the same: one magnet is north up and the other magnet is south up.

Here is a stack of 4 duals and a stack of six singles, which, of course, have been separated off their keepers (not shown).

To remove:

Place the edges of the keeper in a vice.

Don't even think about letting the vice touch the magnets!

Squeeze hard until the keeper plate warps. Your objective is to either

bow-in or to bow-out the keeper metal. The magnets come

off easily without damage.

Once they are off, they are easily damaged.

And that is true despite a nice looking

chrome or nickel coating.

All Neos measure approximately Br=1000mT

Neos: Br=1000mT

Neos: Br=1000mT

|

Bought at Novelty store

Br=1000mT

|

Ceramic (Ferrite) magnets

Strontium Ferrite

Ceramic

1961-1970, 1978

|

Sintered Ferrimagnetic Ceramic compounds

Ferrite magnets are derived from iron oxides such as Hematite (Fe2O3) or Magnetite (Fe3O4)

As well as barium or strontium oxides.

Although Ferrite is brittle, and prone to chipping, it is cheap to produce.

Magnetization is temporarily lost linearly with temperature.

Hardness is 7 on the Moh scale.

Br Br Hc

Grade-1 2.2kG 220mT 1900 O

Grade-10 4.2kG 420mT

Ceramic-5

Ceramic-8 3,900G 390mT 3050 O

Ceramic Ring

Ceramic Ring

2.8cm diameter

0.5cm Length

R=1.4cm

B=7.12 at one radius

I am not even going to entertain the notion of calculating this Br.

The hole is too big.

Here are some more ceramic magnets with holes:

Here are some more ceramic magnets with holes:

Magnetron magnets

|

Do not throw away any microwave ovens without going after the magnets.

The disassembly and retrieval is intuitive if you have a screwdriver and

and somewhat of a don't care attitude.

Dual magnetron magnets from a microwave oven.

One is thicker than the other:

thick one is 1.35cm, thin is 1.10cm

diameter is 6.05cm

inside diameter is 2.13cm

At surface (flush) in center of hole:

both : N41.0mT S40.4mT

thick: N41.8mT S66.8mT

thin : N66.6mT S42.7mT

at one radius:

Both : N20.28mT S20.44mT

thick: N18.9 mT S10.5 mT

thin : N 8.76mT S17.4 mT

Evidently the force is graduated from face to face.

For a magnetron the poles are grossly different, but when combined average out the same.

Speaker magnet

|

How to disassemble a speaker magnet

Ceramic Ring Speaker magnets...

To remove:

First, wear glasses and gloves.

Do not heat or bang on a magnet.

There is no glue in between the magnet and its keepers. The glue would only increase reluctance.

There is only glue on the edges, and this is easily broken.

Choose a hammer with the same mass (weight) as

the center section. Tap the center cone area, with the bulk of

the magnet on a soft towel or carpet.

The momentum shock will be minimized on the magnet itself.

The shock of inertial vibration will fracture crack the glue.

If you have chosen your weights well, then theoretically, you may hit as hard as you want: the magnet will be

unaffected.

Work a knife evenly around

the seam. You will find that now you can tap the blade in between.

Conservation of Momentum

|

Do not support the magnet portion on the jaws of a vice, and think that you can drive the center keeper through.

I tried this. You will chip the edge of the fragile magnet!

This stupid idea is how I chipped the edge on my otherwise perfect magnet - as you can see in the picture.

One the other hand, this other way - of using carpet and the conservation-of-momentum - works great.

Do not support the magnet portion on the jaws of a vice, and think that you can drive the center keeper through.

I tried this. You will chip the edge of the fragile magnet!

This stupid idea is how I chipped the edge on my otherwise perfect magnet - as you can see in the picture.

One the other hand, this other way - of using carpet and the conservation-of-momentum - works great.

Now, for a really big speaker magnet...

Now, for a really big speaker magnet...

You must use carpet or foam on the underside. Use a hammer with the same weight as the bottom keeper.

I am using a sledge instead of a ball peen for extra weight - not hitting force!

Otherwise you will damage the fragile magnet. The shock vibration must not extend into the magnet.

You must not expose the ceramic to excess shock. One smart tap broke this bond. You will not know the bond

is broke by inspection. You must probe with a sharp knife blade. If you can tap a blade in between,

then evenly widen the gap with screwdrivers.

After the bottom piece is pried off, place a punch on the inside lip of the flat keeper piece. It should

break the glue bond with a gentle tap.

This thing has a diameter of 13.39cm, and weighs 10.2 Newtons.

This thing has a diameter of 13.39cm, and weighs 10.2 Newtons.

It has a thickness of 1.95cm.

It has an inside diameter of 5.85cm

At surface (flush), and in the center of hole:

N=flush North, and S=flush South.

N40.6mT S41.5mT

This happens to be the same value as the magnetron ceramic magnets, except the poles

are nearly symmetric (with the same value) with this one.

At the Radius distance z 6.75cm distance:

aprox 8.9mT

And it came out easily with no chips!

Ceramic rectangle

Ceramic rectangle

(With magnetic path loss hole)

2.55cm X wide

1.8cm Y high

4mm L Length

R=1.2cm equivalent

B=9.24 at one Z radius (z=1.2cm)

Because of the hole, Br>200mT

(Ceramics range from 200mT to 400mT)

Ceramic rectangle

purchased at HarborFreight.

Ceramic rectangle

purchased at HarborFreight.

Since I am crazy about magnets,

I will through away a couple of dollars, just to see the Br value.

And this one I can derive; there is no hole in the middle.

4.80cm X wide

2.20cm Y high

1.00cm L length

R=1.834cm equivalent

B is 18.6mT at measurement z (z is 1.90cm)

Br=296mT

The following magnets that I have around the house use this equation...

The following magnets that I have around the house use this equation... Or, solving for Br...

Or, solving for Br...

These next three are much better: twice as strong.

These next three are much better: twice as strong.

Neos: Br=1000mT

Neos: Br=1000mT

Ceramic Ring

Ceramic Ring

Do not support the magnet portion on the jaws of a vice, and think that you can drive the center keeper through.

I tried this. You will chip the edge of the fragile magnet!

This stupid idea is how I chipped the edge on my otherwise perfect magnet - as you can see in the picture.

One the other hand, this other way - of using carpet and the conservation-of-momentum - works great.

Do not support the magnet portion on the jaws of a vice, and think that you can drive the center keeper through.

I tried this. You will chip the edge of the fragile magnet!

This stupid idea is how I chipped the edge on my otherwise perfect magnet - as you can see in the picture.

One the other hand, this other way - of using carpet and the conservation-of-momentum - works great.

This thing has a diameter of 13.39cm, and weighs 10.2 Newtons.

This thing has a diameter of 13.39cm, and weighs 10.2 Newtons. Ceramic rectangle

Ceramic rectangle