index

Most of this information is for my own use, but others find it interesting too.

Some preliminary information...

Some preliminary information...

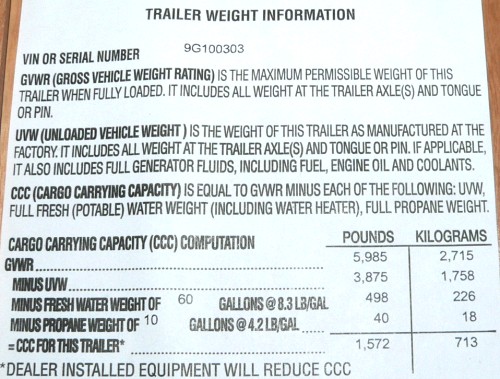

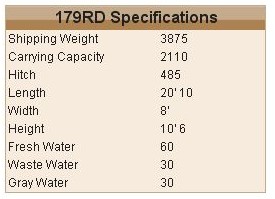

Trailer:

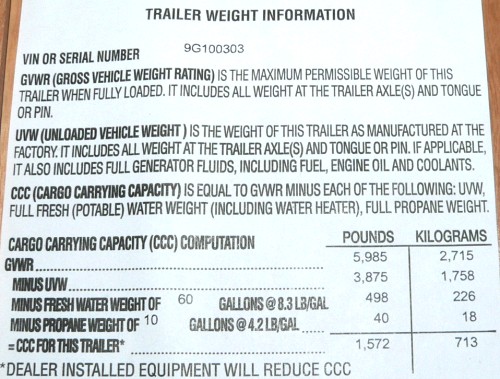

Trailer GVWR Gross Vehicle Weight Rating (Total of Dry and Contents) is 5985 lbs.

This rating should never be exceeded.

There are certain normal part-of-the-trailer contents:

Water

Propane

Batteries

If you subtract these, you have a max of 1572 lbs for personal stuff.

I forgot the batteries at 50 lbs each, 100 lbs. So 1475 lbs for personal stuff.

That is plenty for clothes and food. As far as the trailer is concerned, I am good for Contents.

I am going to hazard a guess at the Trailer GAVW:

The Rating is 5985 lbs. I can not go over that.

Dry Trailer: 3875 lb.

Propane: 498 lb.

50% Fresh Water: 240 lb.

50% Grey and Black: 240 lb.

Clothes: 50 lb.

Food: 100 lb.

Misc: 100 lb.

Total: 5100 lb. (Batteries may be part of the Dry.)

As far as the trailer is concerned, I am good for Contents.

As far as the Van is concerned...

As far as the Van is concerned...

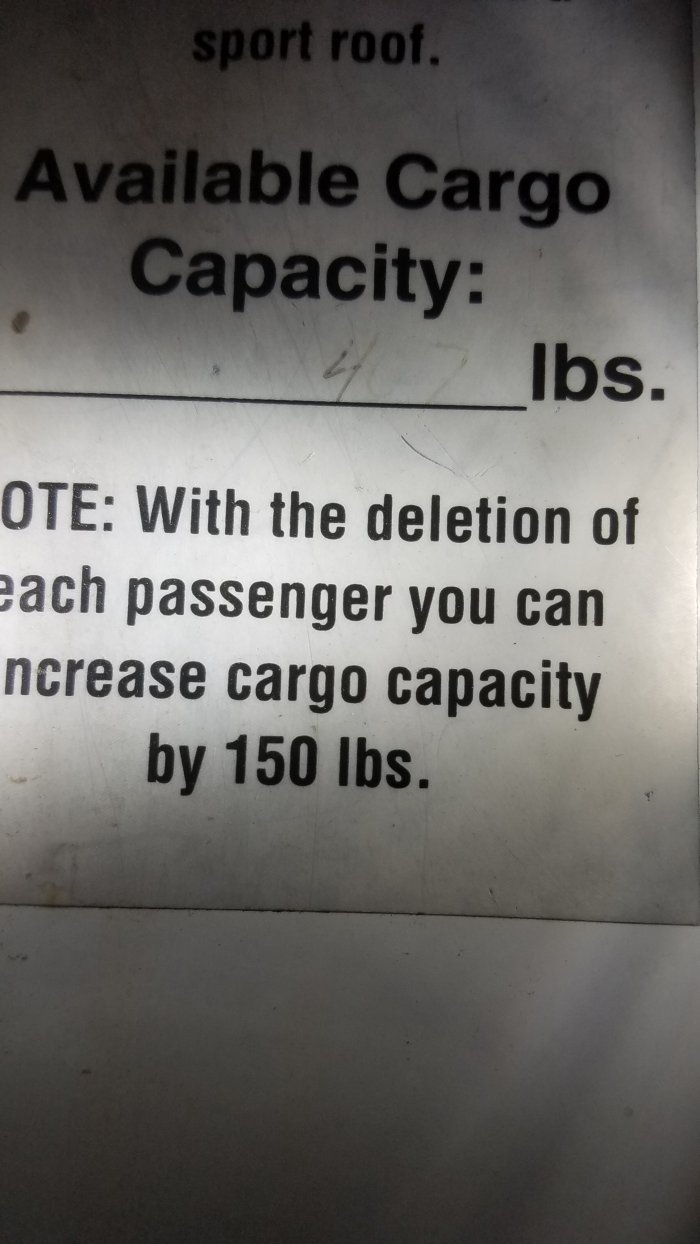

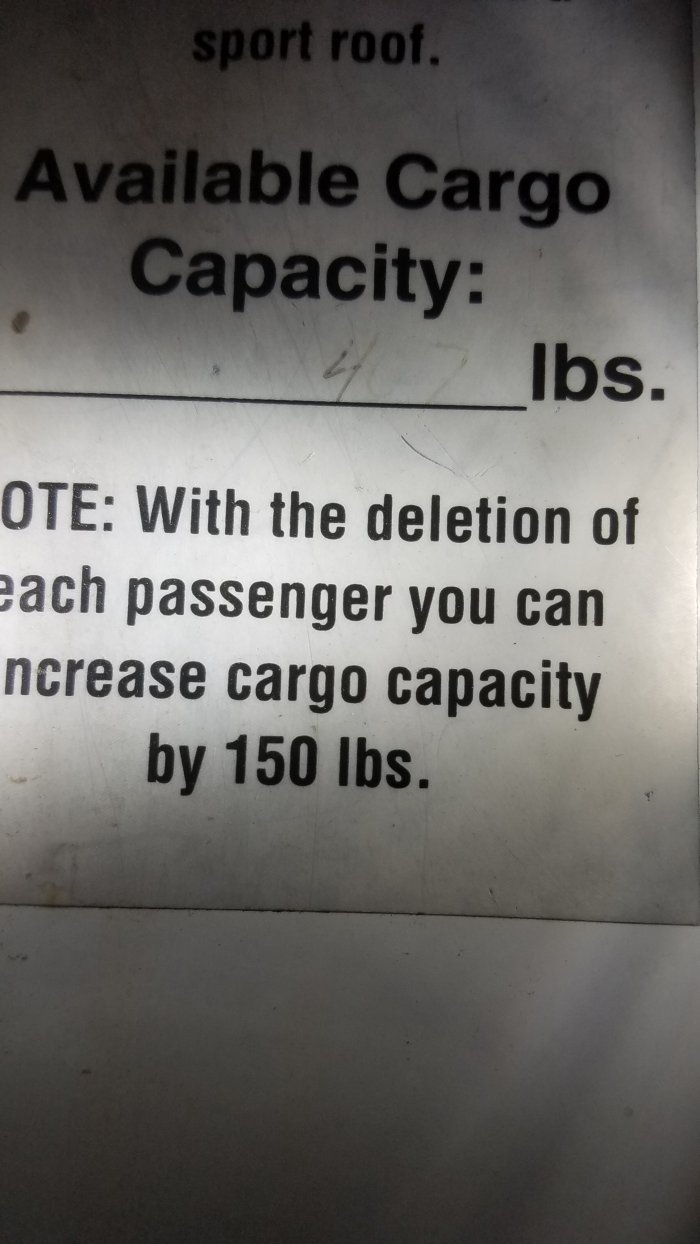

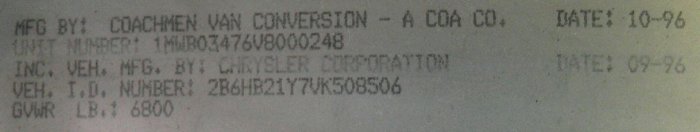

This sticker in the car door jam relates to this modified High Top Sport Roof, and is for Cargo.

This sticker in the car door jam relates to this modified High Top Sport Roof, and is for Cargo.

And states 407 lbs is left as Cargo, after 7 (150lb) people. (Gas is part of Curb)

Max Payload is (1050 lb with 7people) + (407 lb Cargo).

Custom Van Max Payload is 1,457 lb; According to sticker with Custom HighTop and Towing package.

Standard Van Max Payload is 2,570 lbs

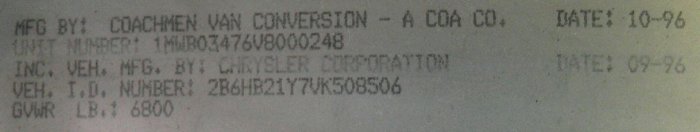

GVWR is 6800 lbs.

GVWR is 6800 lbs.

If Payload Rating is 2570 lbs, then Curb Weight is (6800-1257) or 4,230 lbs Stock

If Payload Rating is 1,457 lbs, then Curb Weight is (6800-1457) or 5,345 lbs Custom

I can not believe this; Is a fiberglass top heavier than a steel top?

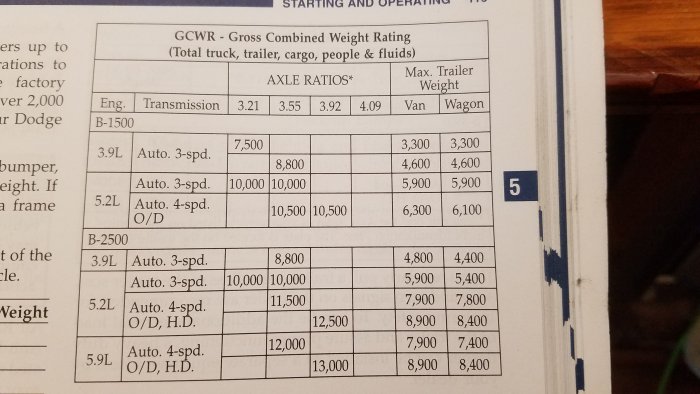

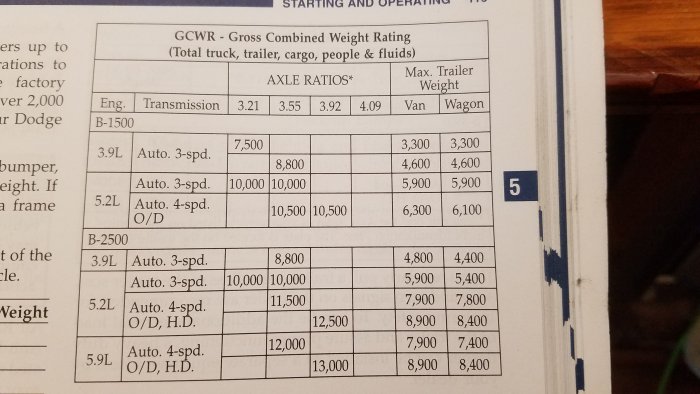

Van B2500 GCWR is 12,500 Combined lbs. And Max Trailer Weight is 8,900 lbs.

Van B2500 GCWR is 12,500 Combined lbs. And Max Trailer Weight is 8,900 lbs.

Maximum Trailer Weight GTWR with a Standard Van (12,500-4200) = 8300 lbs.

Maximum Trailer Weight GTWR with full Custom Van (12,500-5345) =7155 lbs.

Max Trailer Weight of 8,900 lbs is obviously in error.

The Van (Tow Vehicle) GVWR(rating) is 6800 lbs, from Dodge.

The Van GVWR is also rated 6800 lbs from the Custom High Top Sticker on the vehicle.

A dry Van Curb Weight, for an unmodified van is 4200 lbs.

So, Max Contents, Payload, is (6800 - 4200) lbs, or 2600 lbs.

2600 lbs is the Stock Van's max Payload.

But the sticker implies (6800-5123=1677.5).

The Custom High Top Dry Weight is 5,123 lbs.

If I took it to a weigh station, it should weigh more than a normal van.

Two people is 300 lbs, Misc is 100 lbs. Call it 400 lbs for Personal Contents, or Cargo.

Therefor, the full weight of my van should be about 5,345 + 400 is 5,745 lbs GVW.

But the Payload is not just about Personal Contents. When towing there is one more item, and it is very important.

The Trailer also contributes to part of the Van's Payload; It is the Vertical Hitch Weight of the trailer.

This "foreign" weight is very important. It comes from the trailer, and is imposed on the Tow Vehicle. It is called Tongue Weight.

The actual Gross Vehicle Weight GVW (5,745 lbs), can not exceed the Gross Vehicle Weight Rating GVWR (6800 lbs).

We have plenty left over for the tongue weight.

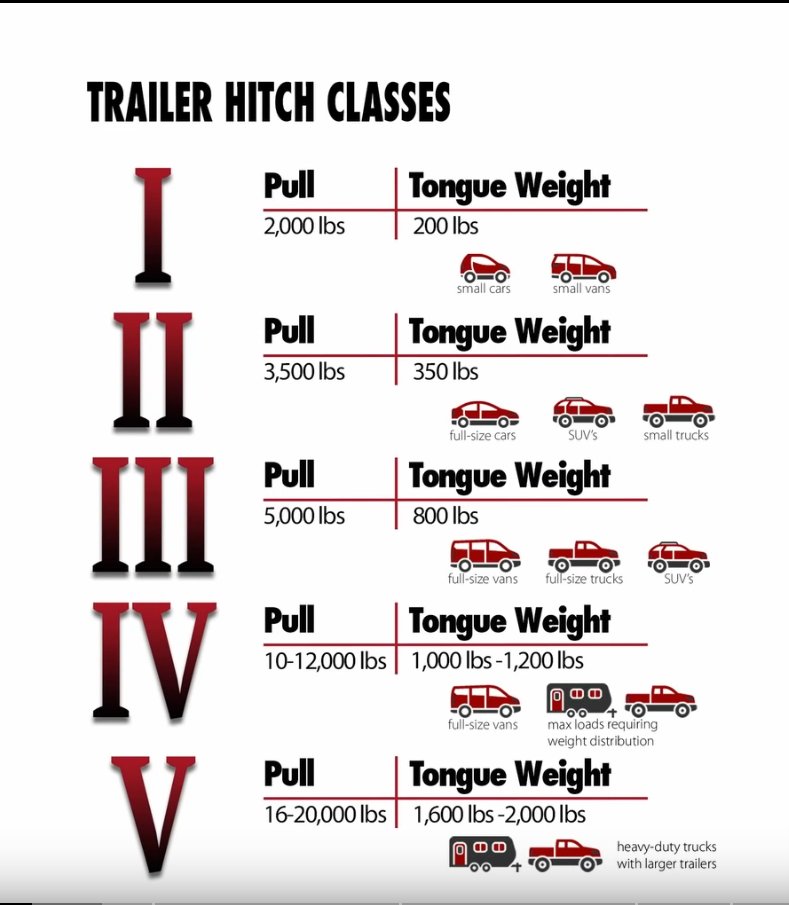

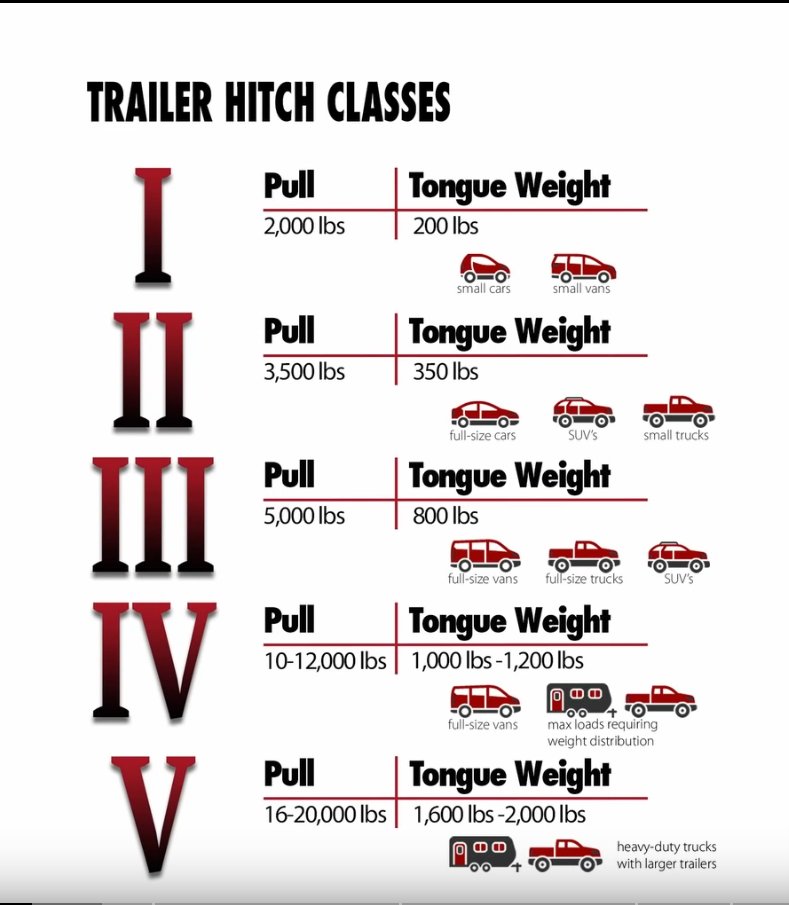

Tongue Weight TW should be 10% to 15% of total Trailer Weight GAW.

Tongue Weight TW should be 10% to 15% of total Trailer Weight GAW.

IE ideal would be 12.5%. For example 485/3875=12.5%

Too light, the trailer will develop a swaying action, and tip over. Too heavy, and the Payload of the Tow Vehicle will be exceeded.

Weight Distribution should be used if Actual Trailer GAVW is greater than 50% Van GVWR max rating.

If I put in the Trailer GAVW (Gross Actual Trailer Weight) to the Van GVWR (Gross Vehicle Weight Rating),

which is 5100/6800, or 75%. (75% is over the 50% value.) Then I need a Weight Distribution Hitch WDH.

...And to think that for a season, I drove without the bars.

I remember that I did not like the way it handled in the wind, and I was afraid of fast moves.

The bars do make a difference.

EAZ-Lift Elite 14000lbs

with Round Bars

The hitch itself is great, but it sure is heavy.

Class 4 Heavy Duty

Weight-Distribution (with the torsion bars):

(MGTWR) Maximum Gross Trailer Weight Rating is 14000lbs

(MGTWR) Maximum Gross Trailer Weight Rating is 14000lbs

My trailer weighs 3875 lbs plus contents - and that is a LONG way from 14000 lbs!

(MVHC) Maximum Vertical Hitch Capacity is 1400 lbs with bars.

(MVHC) Maximum Vertical Hitch Capacity is 1400 lbs with bars.

And 600 without bars. So depending on adjustment the vertical pounds has a large range: between 600 to 1400 lbs.

My trailers tongue weight, measured with bathroom scales, is 230 lbs.

But 230 highlights a more dangerous point: 230 lbs is not enough tongue weight for safety. Tongue weight should be at least 10% of trailer GVWR.

In the example, for a 3875 lbs, I need at least 485 lbs. If I do not have it, the trailer can tail wag or sway.

The instability will grow, the tail wag will increase, and the trailer will flip over. And usually take the tow vehicle with it.

However, fortunately in my case, I am not pulling with a truck. I am pulling with a van which has a shorter distance from ball to the rear axil.

Ideal would be for the tongue weight to rest directly over the rear axil - like a fifthwheel.

And then the problem is almost totally eliminated.

As a side note, my bathroom scales were going to be exceeded, and I may have temporarilly removed the two propane tanks, which weigh about 100 lbs.

If that is the case, and I can not remember totally, the tounge weight may be 330 lbs; still light but better.

But it is a mute point: propane tanks can be empty. To add to the problem, the Keystone was designed with the 60 gal fresh water tank BEHIND the rear axil.

If it is full, which is never the case, the aft fresh water tank can leverage the tounge to even be lighter.

Why havent more Keystones flipped over?

Weight-Carring (without bars):

(MGTWR) Hitch Maximum Gross Trailer Weight Rating is 6000 lbs, without bars.

(MGTWR) Hitch Maximum Gross Trailer Weight Rating is 6000 lbs, without bars.

(MVHC) Hitch Maximum Vertical Hitch Capacity is 600 lbs.

(MVHC) Hitch Maximum Vertical Hitch Capacity is 600 lbs.

But this will be limited by the Trailers Vertical Hitch capacity which is 478 lbs.

Parasitic weight:

Basic hitch unit is 40 lbs, actually 40.6 lbs.

4 inch rise, 2inReceiver, 1.25 ball shank hole, 2 5/16 ball

Bars are 29 lbs.

Total is 70 lbs dead weight.

Total is 70 lbs dead weight.

A lot of weight!

Travel Trailer 2009 West 179RD

TT GVWR 5985 lbs

TT Dry Weight 3875 lbs

TT Cargo 2110 lbs

TT Hitch capacity 485 lbs

TT Tires ST205/75D-14C, RIM 15x5

TT Tires B:1,430 lbs at 35 psi, C:1,760 lbs at 50 psi

TT Length overall (brochure): 20ft 10in

TT Length overall (Measured): 22.5 feet

TT Width (brochure): 8ft 0in

TT Width Outside (measured): 8ft 1 inch

TT Height (Measured): 10 ft 8 in (top of AC)

Tongue: 3 foot 6 inches

Box: 17 feet 6 inches

Rear bumper and Spare Tire: 16 inches

TT Length overall (Measured): 22.5 feet

TT Fresh 60 gal

TT Fresh 60 gal

Modified to Insulated, Heated.

TT Grey 30 gal

TT Grey 30 gal

TT Black 30 gal

TT Black 30 gal

TT LPG Canisters

TT LPG Canisters

TW 24.9lb steel/ea, 18 pounds Al/ea, Empty weight, Tare

T 11.3 Kg

TC Canada ok, 16 bars canister working pressure, = 232 psi

(Propane LPG is 177 psi at 100F degrees)

08A08 2008.Aug Manufacture Date

The old regulation of every 10 years has been rescinded.

New recertification is 12 years. And then every 5 years after that.

Therefor, purchasing a new canister is a viable option.

Holds aprox 30 lb propane/ea (7.25gal of propane/ea, 4.11 pounds per gallon)

14.5 gal Propane Total in two bottles

WC 7 1/4 gal, WC 32.4 liters

BTU: 649,980BTU/ea canister, Closer to 648,000BTU not full.

BTU: 21,600BTU/lb

Aprox 55lb total/ea, (Propane + Canister)/ea

Aprox 110 lb tongue weight Both canisters

TT WaterHeater 6 gal

TT WaterHeater 6 gal

I adjusted for a static four inch rise with the hitch,

and this gives a perfect level of the van and a perfect level of the TT, with 15lbs in AirBags.

Level gives the trailer front axil tires the same weight as the trailer back tires.

Originally the dealership placed the ball height at second to maximum.

Needless to say, I drove around with the front of the trailer looking up

to the sky, and the trailer weight shifted off the front axle to the back axle.

I took the TT back to CusinGary and insisted they "make it level".

The guys told me not to worry; the thing would be level as soon as I

packed it up with stuff. I had to buy a crescent wrench that was big enough,

and lower it myself. I have found four inches is perfect.

Also, anything over 15 or 20 lbs of air will rise an inch or two too much,

and air makes a big difference on rise and ride.

The ball:

Standard 2+5/16 ball

Keystone travel trailer manufactures got that one RIGHT, for once.

(The ball itself, or actually its shaft, is rated at 10,000 lbs)

The whole crowd of disciples began joyfully to praise God in loud voices for all the miracles

they had seen:

The whole crowd of disciples began joyfully to praise God in loud voices for all the miracles

they had seen:

Luke 19:37

|

The only thing that loads down my van is the trailer hitch itself. The hitch

is very heavy.

Van, 1997, 2500 RamVan, 3/4 ton, Light Duty Truck

Van, 1997, 2500 RamVan, 3/4 ton, Light Duty Truck

modified Custom from Coachmen, extended Sport Roof

Van, trailer-tow pack, 3.50 axle ratio, oil cooler, 46RE Tran, 4sp Ovr

Power: 5.2L, 318cc, 220HP, 300 ftlb

Gas capacity: 133L, 35gal Tank

Drag Coefficient 0.48, Frontal area is 36.27 sq ft

Alternator: 117 Amps.

I measure these gas milages:

19.6 miles/gal straight roads, (optimum driving, less than 55 mph)

19 miles/gal freeway speeds

10 to 16 miles/gal town

10 to 12 miles/gal towing

Van GVWR Gross Vehicular Rating (Vehicle and contents): 6800 lbs.

Van GVWR Gross Vehicular Rating (Vehicle and contents): 6800 lbs.

Van Curb Weight: aprox 4200 lb

Van Curb Weight: aprox 4200 lb

Van Cargo Capacity while with seven 150lb passengers: 407 lbs.

Van Cargo Capacity while with seven 150lb passengers: 407 lbs.

Van GCWR Gross Combined Weight Rating (Tandem, GVWR Van + GVWR Trailer): 12,500 lbs

Van GCWR Gross Combined Weight Rating (Tandem, GVWR Van + GVWR Trailer): 12,500 lbs

Van Pulling Weight Rating: 8,900 lbs towing.

Van Pulling Weight Rating: 8,900 lbs towing.

Van Maximum Towing Capacity: 8,900 lbs towing.

This 8,900 is optomistic, and is eaten away by Contents of both Van and Trailer...

12,500 lbs - Van's 4900 lbs GVAW = 7,600 lbs.

This 7,600 lbs is more realistic, and is reserved for Trailer and contents.

7600 lbs is the max that any Trailer and Contents can be.

My trailer and contents is 5100 lbs. I made it with over 2,000 lbs to spare.

Van supportable Tongue Weight: 800 lbs vertical.

Van supportable Tongue Weight: 800 lbs vertical.

The Van's 800 lbs is eclipsed, or limited, by the Hitche's 600 lbs weight rating (without bars).

I made it with over 200 lbs to spare.

Van GAWR, Gross Axle Weight Rating:

Van Front 3300lbs with tires 35 lbs,

Van Front 3300lbs with tires 35 lbs,

Van Rear 3850 lbs with tires 41 lbs

Van Rear 3850 lbs with tires 41 lbs

Van tires: P235/75R15XL

Van tires: P235/75R15XL

Turning Radius:46.2 feet

Turning Radius:46.2 feet

Ground Clearance: 7.2 inches

Ground Clearance: 7.2 inches

Measured Wheel Base: 10 ft 7.5 inches. Front bumper 33 inches. Back axil to hitch ball: 50 inches.

Measured Wheel Base: 10 ft 7.5 inches. Front bumper 33 inches. Back axil to hitch ball: 50 inches.

Total length of van, ball to front bumper: 17.5 feet

Van height: 7.5 feet

Van height: 7.5 feet

Van + Trailer: 17.5+22.5 = 40 feet

Van + Trailer: 17.5+22.5 = 40 feet

Here is another exercise, concerning the hitch...

Here is another exercise, concerning the hitch...

The objective is to not ever have to remove the spare tire before a trip.

This is only an experiment, as all efforts actually failed.

Crank handle will touch. Crank has to go!

There remains the possibility that an electric replacement will work.

But it looks to close to call.

I always carry my hydraulic jack, that can replace the crank.

The hydraulic jack is shown under the tongue.

Later, I found that the two stabilizer sizers jacks in the front each individually have plenty of power

to lift the tongue. So there are four alternatives:

1) Replace the crank after every move. (Three bolts.)

2) Use a portable jack.

3) Use the onboard stabilizer jacks.

4) Upgrade to motorized crank.

So, to begin: I begin by slowly placing the Van in a hard right hand turn. Steering wheel is turned as

sharp as it can be. Continually stoping and jumping

out of the van to take measurements. Finely, the trailer is tracking around with no further

change in the distances, with a radius of 15.25 feet. This is as close as it is going to get.

...Unless, I am going backwards.

A view from top, parallel with spare tire wheel cover.

OK, I removed one propane tank. It was going to hit for sure.

Side view, parallel with spare tire wheel cover.

Again, the propane tank will hit for sure.

And the crank will probably hit, even if converted to electric.

It is just way too close to call.

Woofie is intently watching all the measurements...

A 45 degree view, parallel with spare tire wheel cover.

The cable is coiled around what used to be the crank. I would be nervous about replacing it.

Before I would do that, I would redesign the spare tire carrier. Two inches can be hack sawed out of

the three brackets (not shown) and rewelded. The spare tire would be mounted two inches closer to the door.

About 4.5 inches from the nearest object, which is the hold down bracket.

The piece of wood is just temporary. The piece of wood serves as an "artificial" tank.

Obviously, the second tank has to go, because the sides of the tank are much bigger than

the base. The closest thing that remains is this backet, at about 4.5 inches from the spare tire cover.

Here is how to reduce a two-tank holder to a single tank...

And without buying a a new single tank holder.

And you can change your mind - at any time - and add the second tank again.

Replace the wood with something more durable.

I choose a 24 inch section of black ABS Two-inch schedule 40, for under two dollars.

I painted the ABS a white to match everything else on the tongue.

A second reason is that ABS can not withstand loads above 140F degrees.

And will deform at even lower temperatures.

If you get some white PVC schedule 40,

you will still have to paint it, otherwise PVC will photo degrade and

become brittle. I would rather have a slow failure than a catastrophic one.

Actually, I should have gotten CMT electrical conduit. It is light enough, and will last forever.

Cut the ABS to the height of the missing propane tank: 21 inches.

Cut two notches so that the height would be approximately 20.5 inches.

Use an end plug or end cap, put a screw into base to secure to propane platform.

Place ABS tube over plug. Now the bottom of the tube can not move.

Tighten down the top over both the phantom tank and the one remaining real tank.

Now this two-tank propane holder can be used for a single propane tank.

... and I never have to remove the spare tire on the van anymore!

Actually, it will not work. I do not want to give up one propane tank, nor will I give up the crank.

Calculating Tongue weight by placing different weights on back bumper.

Calculating Tongue weight by placing different weights on back bumper.

(with 5 lbs air)

12.75+1/16 inch empty = 0 lbs 10.25 at running board 6 ft from bolt

12.75 hitch 40 lb = 40 lbs

12.75-1/16 inch hitch 40 lb +bars 30 lb = 70 lbs

12.50 me, 168 lbs = 168 lbs

12.25 168 lbs + 40 lb hitch = 208 lbs

12.0 trailer (calculated aprox) = 230 lbs to 300 lbs

Should be linear. It is not. Air bags and Leaf Springs must not be coming into play at the same time.

Starts out hard (1000 lb/inch), then changes to soft (233 lb/inch).

Ridicules! This method will not work at all.

Another place...

13+1/4 Hitch = 40 lbs

12+1/4 Trailer + Hitch = 370 lbs One inch for trailer

--- trailer (Measured) = 330 lbs Tongue weight

13+1/8 Hitch 8 lbs air = 40 lbs

13+1/2 Hitch 15 lbs air = 40 lbs half inch / 10 lbs air

So, I borrow the bathroom scales and measure 330 lbs tongue weight. No guessing anymore!

Quite definitive!

Also measure the trailer drop: one inch, plus or minus 1/4 inch. It changes each time

it is measured, and does not move smoothly as weight is added or subtracted. The suspension

is kinda "grippy".

You could put oil on the leaf springs to help the leaves slide over each other, but you would

still have to contend with such a short travel for the measurement.

Also, I measured the Air Bags lift as a half inch for every 10 lbs air.

The tongue weight is with an empty fresh water tank, which is aft of the center of the two axles.

With a half load of fresh water, which is 30 gallons or 240 lbs in the back of the TT, then the front

could get real light. I could loose control with yaw oscillations, as well as a lot of bobbing, as well

as loss of front wheel steering.

With a full fresh tank the tongue weight could go to zero - or even a minus.

Can not risk the handling instability!

For my thoughts are not your thoughts, neither are your ways my ways, declares the LORD.

For my thoughts are not your thoughts, neither are your ways my ways, declares the LORD.

Isaiah 55:8

|

Now, I should keep that heavy torsion hitch!

...thought I was rid of it. Can never do what I want to do.

Some preliminary information...

Some preliminary information... This sticker in the car door jam relates to this modified High Top Sport Roof, and is for Cargo.

This sticker in the car door jam relates to this modified High Top Sport Roof, and is for Cargo. GVWR is 6800 lbs.

GVWR is 6800 lbs.  Van B2500 GCWR is 12,500 Combined lbs. And Max Trailer Weight is 8,900 lbs.

Van B2500 GCWR is 12,500 Combined lbs. And Max Trailer Weight is 8,900 lbs.

TT LPG Canisters

TT LPG Canisters Van, 1997, 2500 RamVan, 3/4 ton, Light Duty Truck

Van, 1997, 2500 RamVan, 3/4 ton, Light Duty Truck